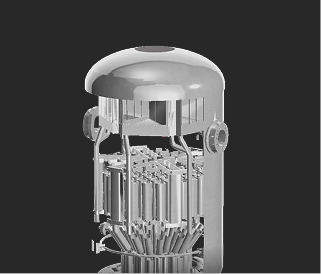

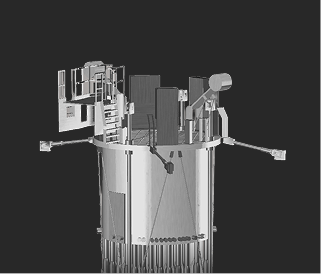

Step into a fully immersive 3D nuclear power plant and explore Framatome’s cutting-edge products and services. Move freely through the environment, interact with points of interest, and discover the technologies powering safe, reliable, and low-carbon energy for the future.

0%